Hydrogen

As the industry expands, hydrogen refueling stations are becoming more common. We provide some of the best-in-class financial model templates analyzing the economics of different types of hydrogen production projects by leveraging the potential of green energy sources.

Blue Ammonia using Natural Gas – 3 Statements, Cash Waterfall & NPV/IRR Analysis

An integrated and comprehensive Blue Ammonia Production Plant Model that…

Blue Hydrogen using Natural Gas – 3 Statements, Cash Waterfall & NPV/IRR Analysis

An integrated and comprehensive Blue Hydrogen Production Plant Model which…

Green Ammonia from Renewable Energy Financial Model

This comprehensive 40-year tool aid investors in evaluating potential risks…

Clean Hydrogen Production Project Economic Model

This is a detailed and easy-to-use hydrogen production from methane…

Discounted Big Bundle Real Estate Valuation and Financial Models

One Excel file for this bundle of Valuation and Financial…

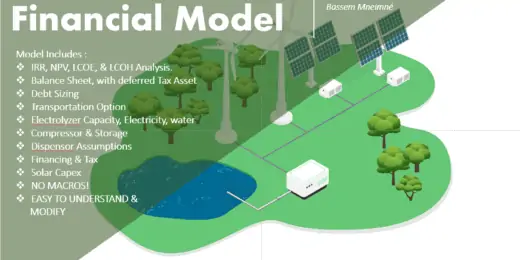

Green Hydrogen (Electrolysis) Production Financial Model

This green hydrogen financial model template builds a multi-year financial…

Yellow Hydrogen from Solar Energy Financial Model

Deciding whether to invest or not in producing yellow hydrogen…

Green Hydrogen Production from Wind Energy Financial Model

The Green Hydrogen from Wind Financial Model aims to comprehensively…

Green Hydrogen Project Financial Model (Electrolysis & Onsite Solar Plant)

A Project-Level Financial Model to assess the financial feasibility of…

Hydrogen Gas- Tariff Calculator with Integrated Financial Statement and Cash Waterfall

The Perfect tool to assess the financial feasibility, proposal to…

Hydrogen Gas Equipment Manufacturing and Sales Model – DCF Valuation Model

Hydrogen Gas Equipment Manufacturing and Sales Model – Discounted Cash…

Biomass to Hydrogen Gas PPP Project Model Template

Biomass to Hydrogen Gas PPP Project Model with 3 Statements,…

Hydrogen Gas Sales & Tolling Business Plan and Valuation Model

Hydrogen Gas Sales & Tolling Business Plan and Valuation Model…

Green Hydrogen (Simple Electrolysis Financial Model)

The Model Incorporates data provided by different available sources to…

Gasoline and Charging Station Financial Model

Investors can assess the viability of setting up and investing…

The Future of Hydrogen Energy

Hydrogen, represented by the chemical formula H2, is not just another element on the periodic table; it's the universe's most abundant element and a cornerstone in the quest for sustainable energy solutions. Its potential as a clean energy source is vast, but like all promising ventures, it comes with its set of challenges and opportunities. Understanding hydrogen production methods is pivotal to grasping the intricacies of the energy sector, especially as we stand on the brink of an energy revolution. From the nuances between blue and green hydrogen to its seamless integration with the sustainability of natural gas and existing infrastructures, the hydrogen industry is a tapestry of innovation and potential.

As we delve deeper into this topic, we'll uncover the production methods, financial incentives, and multifaceted applications of hydrogen. Whether you're an investor, an enthusiast, or someone curious about the benefits of hydrogen and the future of energy, this journey through the hydrogen landscape promises to be both informative and enlightening.

The Sustainability Problem of Natural Gas

According to the United States Environmental Protection Agency, the oil and natural gas infrastructure is a complex network that includes wells, gas gathering and processing facilities, storage units, as well as transmission and distribution pipelines. These integral components collectively constitute the natural gas cycle, a sophisticated process that facilitates the extraction, processing, and delivery of natural gas from subterranean reserves to the end consumer.

In 2022, global natural gas production reached approximately 4.09 trillion cubic meters, marking a marginal decline compared to the preceding year. Despite this slight contraction, the global share of natural gas within the energy mix is anticipated to experience growth in the coming years. Notably, Russia, the United States, and Iran stand as some of the most prolific producers of natural gas on a global scale (Source: Statista).

This data underscores the increasing importance of natural gas as a pivotal energy resource, both for its versatility in application and its potential for meeting future energy demands in a more sustainable manner.

Natural Gas produces CO2 Emissions and Greenhouse Gases

The main problem of the current state of the natural gas industry is the unwanted pollution of the environment. Natural Gas emissions are one of the key drivers contributing to global warming and climate change.

1) CO₂ Emissions: While natural gas burns cleaner than coal or oil, it still releases carbon dioxide (CO₂) when combusted. This greenhouse gas contributes to global warming, making the emissions from natural gas a significant concern.

2) Greenhouse Gases: Natural gas primarily consists of methane, a potent greenhouse gas. During its extraction and transportation, methane can leak into the atmosphere, having a more immediate impact on global warming than CO₂.

So, the problem is how to reduce these emissions.

The Solution: Capturing Carbon and Using New Technologies

The solution is to either capture the CO2 and greenhouse gas emissions at their source by using Carbon Capture and Storage (CCS). This can potentially reduce the environmental impact of natural gas combustion to some extent but might not fully avoid it.

The other solution is to find alternatives to natural gas, e.g., by using Electrolysis to produce Hydrogen. Producing hydrogen through electrolysis, powered by renewable energy, offers a carbon-neutral alternative to natural gas-based hydrogen production.

In the following, we are focusing on the Production of various types of Hydrogen.

New Hydrogen Production Methods offer Environmentally Friendly Alternatives

Hydrogen stands out as a beacon in the clean energy landscape. However, its natural occurrence on Earth isn't in its pure form. To tap into its energy potential, we need to extract it from the compounds it forms. While various hydrogen production methods exist, steam-methane reforming and electrolysis are the frontrunners in the hydrogen economic landscape.

Steam-Methane Reforming

Steam-methane reforming (SMR) stands as a predominant method for large-scale hydrogen production, especially in regions like the U.S. The process involves methane (CH4) reacting with steam under high temperatures, typically between 1,300°F to 1,800°F. This reaction, catalyzed by specific agents, produces hydrogen, carbon monoxide, and a small amount of carbon dioxide (CO2). While natural gas is the primary source of methane for this process, other sources such as landfill gas (biogas), biofuels, and petroleum fuels are also utilized. One of the main benefits of hydrogen produced through this method is its economic viability, backed by its affordability and robust infrastructure (Source: Energy.Gov)

However, the environmental implications of SMR, particularly the emission of CO2, have raised concerns. To address this, Carbon Capture, Utilization, and Storage (CCUS) technologies are being integrated with SMR. By capturing the CO2 produced during the SMR process, it's possible to significantly reduce the carbon footprint of hydrogen production. According to a report by Digital Refining, CO2 capture from steam methane reforming is becoming increasingly crucial. The integration of CCUS with SMR not only aligns with the global sustainability of natural gas objectives but also offers a tangible solution to curb carbon emissions from hydrogen production.

While steam-methane reforming offers an efficient method for hydrogen production, its environmental impact cannot be overlooked. The incorporation of carbon capture technologies presents a promising pathway to make SMR more sustainable and environmentally friendly, paving the way for the future of hydrogen energy.

Electrolysis

Electrolysis presents a green solution for hydrogen production. It involves breaking down water into its basic elements: hydrogen and oxygen, using electricity. Many might recall this process from school science demonstrations, but in the commercial world, it's termed "power-to-gas." The primary appeal of electrolysis lies in its eco-friendly nature, producing only hydrogen and oxygen as byproducts. The electricity required for this method can be derived from renewable sources, nuclear power, or even fossil fuels. Essentially, electrolysis offers a sustainable way to produce hydrogen from water and electricity. However, its cost-effectiveness is influenced by the ever-changing prices of electricity, which vary depending on the energy source. (Source: EIA).

In the financial landscape of energy, steam-methane reforming holds the current crown due to its cost advantages. However, as renewable energy prices drop and environmental concerns rise, electrolysis is poised to become a formidable contender. For investors eyeing the hydrogen economic market, understanding the economic dynamics of these production methods is paramount.

Different Types of Hydrogen: Understanding the Shades

In the evolving landscape of renewable energy, hydrogen is gaining traction as a key player. However, it's essential to understand that not all hydrogen is the same in terms of environmental impact. Its classification into various colors is determined by its production method.

Grey Hydrogen: Produced primarily through steam-methane reforming (SMR), grey hydrogen has a significant environmental drawback: it releases greenhouse gases. This method involves reacting methane with steam but without any measures to capture the resulting CO2 emissions.

Blue Hydrogen: This type of hydrogen is also derived from natural gas, using methods like SMR or auto thermal reforming (ATR). The difference between blue and grey hydrogen lies in the carbon capture usage and storage (CCUS) process. For blue hydrogen, the CO2 produced during its generation is captured and stored, reducing its overall environmental footprint.

Green Hydrogen: Green hydrogen is produced by splitting water into hydrogen and oxygen through electrolysis. The electricity needed for this process typically comes from renewable sources such as wind, solar, or hydroelectric power. As a result, green hydrogen production doesn't release any CO2 emissions, making it the cleanest form of hydrogen.

Yellow Hydrogen: This is a specific subset of green hydrogen. When the electrolysis process is powered solely by solar energy, the resulting hydrogen is termed yellow.

While both green and blue hydrogen offer sustainable energy solutions, green hydrogen stands out due to its complete reliance on renewable energy sources and zero CO2 emissions. Blue hydrogen, on the other hand, is a step in the right direction, provided the carbon capture processes are efficient and no other greenhouse gases are emitted during its production. To learn more about the Hydrogen Colors, please read How to Successfully Plan a Hydrogen Project.

Diverse Applications of Hydrogen: From Industry to Clean Energy

Hydrogen, the universe's lightest and most abundant element, holds significant promise due to its clean and energy-dense properties. Here's a breakdown of its applications:

Industrial Applications for Hydrogen

Hydrogen, a versatile and clean energy carrier, plays a crucial role in various industrial sectors. From agriculture to electronics manufacturing, its applications are diverse, driving efficiency and sustainability in production processes.

- Agricultural/Chemical Industry: Hydrogen is pivotal for ammonia production, which is integral for creating ammonia-based fertilizers that boost crop yields.

- Petroleum Refining: Hydrogen is instrumental in refining crude oil into usable fuels by breaking down crude components and purifying the end products.

- Metalworking: Industries harness hydrogen to forge specific metal alloys, such as in the production of stainless steel.

- Welding: The Atomic Hydrogen Welding (AHW) technique utilizes hydrogen for specialized welding processes.

- Electronics Manufacturing: Semiconductors and similar devices often necessitate hydrogen during their fabrication stages.

- Food Production: Hydrogen is a key component in the creation of certain foods, notably hydrogenated oils.

Energy and Power Generation from Hydrogen

Harnessing the power of hydrogen offers a revolutionary approach to energy and power generation. With its potential to replace conventional fuels, hydrogen stands at the forefront of cleaner and more sustainable energy solutions.

- Fuel Cells: Hydrogen fuel cells generate electricity. Imagine a battery that only needs hydrogen and oxygen to produce power; that's essentially what a fuel cell does.

- Electricity Generation: Hydrogen can be burned to produce electricity, offering a cleaner alternative to coal or natural gas.

Hydrogen as a Transport Fuel

The transportation sector is undergoing a transformative shift with the advent of hydrogen as a fuel source. From cars to airplanes, hydrogen-powered vehicles are setting new standards for efficiency and environmental responsibility.

- Cars: Major automobile manufacturers like Toyota with their Mirai model and Honda with the Clarity Fuel Cell are leading the charge in hydrogen fuel cell vehicles. These cars utilize hydrogen gas to power an electric motor, emitting only water vapor and warm air as by-products.

- Trucks: Companies such as Nikola with their Nikola Two and Hyundai with their XCIENT Fuel Cell truck are pioneering hydrogen-powered trucks, offering a cleaner alternative to traditional diesel. (Source: wha-international.com).

- Trains: In Germany, the Alstom Coradia iLint is the world's first passenger train powered by a hydrogen fuel cell, which produces electrical power for traction. This train offers a sustainable alternative to diesel-powered trains, emitting only water and steam (Source: alstom.com).

- Airplanes: The aviation sector is exploring hydrogen's potential as a fuel. Companies like ZeroAvia have successfully tested hydrogen-powered flights, showcasing the potential for commercial aviation to reduce its carbon footprint. (Source: wha-international.com)

Heating

In the quest for sustainable heating solutions, hydrogen emerges as a promising alternative. By blending with natural gas, it provides efficient heating while significantly reducing the environmental impact.

- Blending hydrogen with natural gas offers an eco-friendly solution to heat homes, mirroring the efficiency of conventional heating systems but with a diminished environmental footprint.

Energy Storage – Hydrogen acting as a Temporary Battery

Hydrogen's ability to act as an energy reservoir presents a groundbreaking solution for energy storage. Comparable to a large battery, it holds the potential to revolutionize how we store and retrieve energy.

- Storage: Imagine a large battery that stores energy. Hydrogen can be stored similarly and converted back into electricity when required.

Diverse Conversions

Hydrogen's adaptability extends to various conversion processes, including the production of green ammonia and methanol. These conversions not only support industrial needs but also pave the way for a more sustainable future.

- Ammonia Production: Beyond its use in fertilizers, ammonia, when derived from hydrogen, can be termed as 'Green Ammonia', especially if the source is Green Hydrogen.

- Methanol Production: Hydrogen is also used to produce methanol, which finds applications in various industries, including as a fuel and in plastics.

Demand for Hydrogen

Source: IEA: The Future of Hydrogen (2019)

Following the chart on the "Global Demand for Pure Hydrogen, 1975-2018", global demand for hydrogen has tripled since 1975 and is projected to reach up to 680 million metric tons by 2050 (source: World Bank Blogs). This surge is not just fueled by its industrial utility but also by its emerging role as a clean energy source. As industries and transportation pivot towards sustainability, hydrogen offers a compelling alternative with minimal emissions.

Technological advancements, declining production costs, and supportive global policies are driving hydrogen's viability. The rise of green hydrogen, produced via renewable-powered electrolysis, aligns with global sustainability goals, offering an eco-friendly alternative to fossil fuel-based hydrogen.

The key challenge lies in scaling sustainable production methods like Carbon Capture and Storage (CCS). These technologies are still maturing and require further investment. As hydrogen's applications diversify, including in electric vehicle fuel cells and renewable energy storage, it is poised to become an indispensable part of the global clean energy landscape.

Safety Aspects of Hydrogen and Ammonia

Both hydrogen and ammonia possess properties that make them highly explosive, emphasizing the critical importance of safety in their production and handling. Given their volatile nature, it's paramount that their production, storage, and transportation occur in environments that adhere to stringent safety protocols and standards. As the demand for these energy carriers grows, driven by their potential in clean energy applications, it becomes even more essential for industries and researchers to prioritize safety measures, ensuring that the benefits of these compounds are harnessed without compromising the well-being of workers, communities, and the environment.

Economic Aspects of Hydrogen

How much does it cost to set up a Hydrogen Plant?

Setting up a hydrogen plant is a substantial endeavor that demands careful consideration and financial planning. The costs associated with establishing a hydrogen plant can vary widely depending on several key factors. In this overview, we'll explore the financial aspects of setting up different types of hydrogen plants to provide you with a clear understanding of the investment required.

Large-Scale Industrial Plants:

These are expansive facilities designed to produce hydrogen on a massive scale, catering to the needs of large industries and markets. The undertaking of setting up such a plant is significant, both in terms of financial commitment and scale. The costs involved encompass various aspects, including land acquisition, infrastructure development, technology implementation, and ongoing operational expenses. Due to the magnitude of the investment, conducting a comprehensive feasibility study is essential. Factors such as the availability of raw materials, market demand for hydrogen, and logistical challenges must be carefully evaluated. Large-scale industrial plants offer the advantage of economies of scale but require substantial initial capital.

Plants Attached to Solar or Wind Parks:

These plants are typically smaller in size compared to large industrial plants but come with an environmentally friendly twist. They are integrated with renewable energy sources like solar or wind, harnessing clean energy to produce hydrogen. While the initial setup cost may be lower than that of industrial-scale plants, the integration with renewable energy sources can add to the overall expense. However, in the long run, operational costs may be offset by the use of renewable energy, making it an environmentally sustainable option. The feasibility of such plants largely depends on the availability and consistency of renewable energy sources in the chosen location. Additionally, it's vital to consider storage solutions for both renewable energy and the produced hydrogen.

Small Plants at Distribution Stations:

These compact plants are designed for smaller-scale hydrogen production, typically to meet localized distribution needs or specific applications. The initial investment required for these plants is comparatively lower than that of large-scale facilities. However, the cost per unit of hydrogen produced might be higher due to the smaller scale of production. Small plants are particularly suitable for regions with specific hydrogen requirements or where large-scale production isn't feasible. Assessing the local demand and distribution logistics is crucial when considering such plants.

In summary, the cost of setting up a hydrogen plant is influenced by factors such as scale, integration with renewable energy sources, and plant size. Conducting thorough research and seeking expert advice are pivotal steps in making informed decisions regarding hydrogen plant investments.

Prices for Hydrogen

Source: HydrogenInsight (2023)

Following the table, it's clear that green hydrogen, produced using renewable energy sources, is currently more expensive than its blue counterpart. This cost disparity is influenced by the declining prices of fossil gas, which gives blue hydrogen, derived from natural gas with carbon capture, a cost advantage. However, the price of green hydrogen varies based on technology and region.

For instance, Chinese alkaline electrolyzers are more cost-effective than Western-made equipment and Proton Exchange Membrane (PEM) technology. Notably, China is the only country where green hydrogen is currently cheaper than blue due to its affordable alkaline electrolyzers. Looking ahead, BloombergNEF (BNEF) projections indicate that by 2033, markets using Western-made electrolyzers could achieve cost parity between green and blue hydrogen. As technological advancements progress and investments in renewable energy increase, the cost of green hydrogen is expected to become more competitive (Source: HydrogenInsight)

Hydrogen Cost of Production

The operation of an Electrolyzers Plant or Electrolysis Hydrogen Plant, particularly using polymer electrolyte membrane (PEM) electrolyzers, is influenced by various factors. Here's a comprehensive breakdown:

General Cost Overview:

- Hydrogen production from PEM electrolyzers is currently estimated at $5 to $6 per kg-H2 (Source: energy.gov)

- This estimation is based on existing technology, with electrolyzer capital costs reaching up to $1,500/kW and grid electricity prices between $0.05/kWh to $0.07/kWh (Source: energy.gov)

External Analyses & Future Projections:

- Current external studies suggest hydrogen can be produced within a cost range of $2.50 to $6.80/kg using a mix of renewable and grid feedstocks (Source: energy.gov)

- This aligns with the Department of Energy (DOE) analysis, which projects hydrogen production via PEM electrolysis at a cost of ~$4 to $6/kg for specific conditions (Source: energy.gov)

The cost of electrolytic hydrogen is set to decrease further due to advancements in technology, increased availability of affordable renewable electricity, and reduced capital costs (Source: hydrogen.energy.gov).

Source: IEA: The Future of Hydrogen (2019)

The cost of producing green hydrogen from solar energy is influenced by solar radiation levels. In regions with high solar radiation, solar electricity costs are lower, making hydrogen production more economical. As solar PV costs decline, there's growing interest in using electrolysis for hydrogen production, especially in areas with strong solar radiation (Source: IEA.Org).

Tax Incentives for Hydrogen Energy Plant Production:

As the world leans into sustainable energy, hydrogen energy plant production emerges as a pivotal player. Governments globally are rolling out tax incentives, making hydrogen plants both more affordable and environmentally conscious. For instance, the United States offers massive tax incentives to produce Hydrogen. Let's have a closer look at these tax incentives:

The Advanced Hydrogen Plant Project Credit:

- Aims: Extend a 30% investment tax credit for hydrogen-related projects.

- Eligibility: Projects reducing greenhouse gas emissions by at least 20%.

- Funding: $10 billion allocated for eligible projects.

- Applications: Ranges from retrofitting facilities for low-carbon heat to equipment for recycling and energy efficiency.

Source: Energy.Gov

Section 45V Hydrogen Production Tax Credit:

- Definition: "Qualified Clean Hydrogen" projects have emissions not exceeding 4kg of CO2 per kg of hydrogen.

- Tax Credit Tiers: Based on the environmental footprint of the hydrogen:

- Tier 1: 20% credit (4kg to 2.5kg CO2/kg hydrogen)

- Tier 2: 25% credit (2.5kg to 1.5kg CO2/kg hydrogen)

- Tier 3:4% credit (1.5kg to 0.45kg CO2/kg hydrogen)

- Tier 4: 100% credit (<0.45kg CO2/kg hydrogen)

Source: National Hydropower Association

Key Implementation Challenges:

- Additionality: Clean electricity should originate from new or uprated sources.

- Deliverability: Electrolyzers must source clean electricity from their operating region.

- Time-matching: Aligning electrolyzer consumption with clean energy production is essential.

Assessing the Standards:

- Balancing Act: Striking a balance between strict emission standards and fostering hydrogen energy plant industry growth is crucial.

- Global Insights: Countries like the European Commission, Japan, and Australia provide valuable lessons in crafting hydrogen incentives.

Please note, the above list has been created from our research as per the last update of this article. Tax incentives frequently change, and you should check the latest updates directly with the applicable authorities. As mentioned, these incentives are only applicable to the US, with many other countries offering their own incentives.

With these incentives and global insights, the hydrogen energy plant production industry is poised for transformative growth, promising a sustainable energy future (Source: National Hydropower Association & Energy.Gov).

The Benefits of Green Hydrogen

Hydrogen energy, a topic that has garnered significant attention in recent years, offers a promising alternative to traditional fossil fuels. As the world grapples with the challenges of climate change and the urgent need to reduce greenhouse gas emissions, hydrogen emerges as a beacon of hope. Especially for industries like Oil & Gas, which are major contributors to global emissions, the shift towards cleaner energy sources is not just a choice but a necessity. Let's delve into the compelling advantages of hydrogen energy and why it's becoming the focal point for sustainable energy solutions.

1. A Clean and Renewable Energy Source

One of the most significant advantages of hydrogen energy is its cleanliness. When hydrogen is used as a fuel, the only by-product is water, making it an environmentally friendly energy source. Unlike the burning of fossil fuels, which releases harmful greenhouse gases, hydrogen combustion is virtually emission-free.

2. Abundant and Versatile

Hydrogen is the most abundant element in the universe. It can be produced from a variety of sources, including water, natural gas, and biomass, making it a versatile energy carrier. Its adaptability means it can be used in a range of applications, from powering vehicles to generating electricity.

3. Efficient Energy Storage

Hydrogen can act as an energy storage medium. Energy stored as hydrogen remains intact until utilized, unlike batteries that lose energy over time. This makes hydrogen an excellent choice for emergency generators and mission-critical applications.

4. Reducing Dependence on Fossil Fuels

The Oil & Gas industry, responsible for a significant portion of global greenhouse gas emissions, is actively seeking sustainable energy solutions. With fossil fuel reserves depleting and the environmental consequences of their use becoming increasingly evident, hydrogen offers a viable alternative. Blue and Green Hydrogen, in particular, represent clean energy pathways that can significantly reduce the industry's carbon footprint.

5. Economic Potential

As the demand for clean energy grows, so does the economic potential of hydrogen. With advancements in production technologies and the potential for massive savings in the long run, hydrogen can play a pivotal role in shaping the economies of the future.

6. Supporting Renewable Energy Integration

Hydrogen can be produced using renewable energy sources like wind, solar, and geothermal. This integration means that as we increase our reliance on renewables, hydrogen production can scale up, further reducing our dependence on non-renewable resources.

7. Government Support and Incentives

Governments globally are bolstering hydrogen energy through tax incentives and grants. These financial measures promote its production and adoption, reflecting a commitment to a sustainable energy transition. Such support accelerates hydrogen's role in the global energy landscape.

In essence, the advantage of hydrogen energy is not just another energy source; it's a versatile, efficient, and environmentally friendly solution that holds the promise to revolutionize the way we think about energy. As we continue to explore and harness its potential, hydrogen stands out as a beacon of hope in the quest for a sustainable future (Source: European Parliament & Atura Power).

Financial Landscape of the Hydrogen Industry

The hydrogen industry, with its vast potential and dynamic growth, requires precise financial modeling to navigate its intricacies. Whether you're an investor, a business owner, or a financial analyst, having a robust financial model is crucial to making informed decisions. At eFinancialModels, we offer a comprehensive suite of financial models tailored to the hydrogen industry's diverse facets.

Harnessing Hydrogen: A Sustainable and Profitable Energy Frontier

Hydrogen, the universe's most abundant element, is at the forefront of sustainable energy solutions. Among its various forms, Green Hydrogen, produced through the specific hydrogen production method known as electrolysis powered by renewable energy sources, is gaining significant traction. As these renewable sources become more accessible and cost-effective, Green Hydrogen's potential is magnified, ushering in a plethora of opportunities in the energy sector.

One notable avenue is the production of green ammonia. The Green Ammonia from Renewable Energy Financial Model suggests that as renewable energy becomes more affordable, the production of green ammonia from renewable hydrogen and nitrogen could present a promising investment opportunity. This approach not only aligns with global sustainability goals but also contributes to reducing carbon emissions.

From a financial perspective, the hydrogen industry presents a dynamic landscape. The costs associated with hydrogen production, especially Green Hydrogen, are influenced by various factors, including technological advancements and market dynamics. For instance, the cost of electrolytic hydrogen is expected to decrease further due to advancements in technology and the increased availability of affordable renewable electricity. Moreover, governments worldwide are introducing tax incentives, making investments in hydrogen projects even more attractive.

In essence, the hydrogen industry, particularly the Green Hydrogen segment, promises both environmental and economic benefits, positioning itself as a beacon of hope for a sustainable and financially viable future.